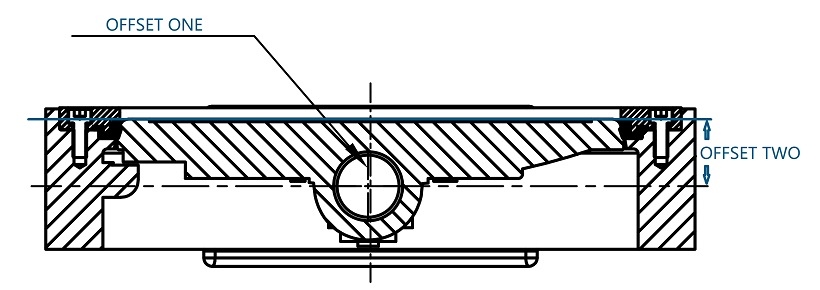

HIGH PERFORMANCE BUTTERFLY VALVE (also called double offset) have two offsets: The first offset of stem is off center to or behind the disc seating face, by the second offset, which shifts the stem off centerline of the pipeline. This double offset creates camming action, moving the disc away from the seat rather than across it, reducing rubbing between the disc and seat as seen in concentric and single offset valves.

The double offset is commonly used for isolation and control applications, as well as higher cycle applications when compared to a concentric design. Most applications are made for higher temperature and pressure than resilient-seated valves. The seats are designed to provide reaction force (contact stress) to disc when in the closed position. This contact stress creates the seal with the disc edge. These designs can be pressure dependent, while others use interference fit provided by a seat energizer for that pressure range. Common body materials include carbon steel, stainless steel and aluminum bronze. Common seat materials include PTFE, reinforced PTFE, TFM, UHMWPE and Inconel.

Additional seat designs for specific application can also include fully metal seated and fire safe (both soft and metal seat). The metal seated design can withstand higher temperature capabilities up to 900°F in dirty service, abrasive service and control applications with hot and dirty service. The fire-safe seated design is used in services at risk for fire, using a soft seated material for isolation while still providing a constant metal-to-metal backup seal to the disc in the event of a fire. The intent of the valve design in these applications is to provide isolation to prevent feeding the flames.

The double offset design can be configured for cryogenic applications; they are most often used in industrial gas applications such as argon, helium, hydrogen, nitrogen and oxygen. The choice of materials is based on the service, focusing on toughness and impact strength of the pressure boundary materials at process temperature. The standards for these applications include strict material specifications along with cleaning requirements for safety and operation of the valves while in service.

FEIDA VALVE is the top ranking China double offset butterfly valve manufacture. The annual output of high performance butterfly valve is more than 100,000,000 set.

The API 607 fire safe high performance butterfly valve is also in FEIDA VALVE product range. Our fire safe butterfly valve is certificated by American Petroleum Institute (API) according to API 607 standards.

FEIDA VALVE also build up a dustless workshop to produce ultra-clean valve for some critical working condition such as nuclear industry, semiconductor industry etc.

In the dustless workshop, FEIDA also produce the food-grade valves. FEIDA food-grade valve is certificated by Food and Drug Administration United States (FDA).

If you are interested in valves, you can contact us directly, email:ethan@feidavalve.com

Scan To Wechat