热销产品

菲达公司的核心产品主要为具有百万次开关性能的高性能蝶阀和各类阀门铸造件

公司成立于2003年

公司注册资金

厂房面积

成功合作客户

核心产品主要为具有百万次开关性能的高性能蝶阀和各类阀门铸造件

01

Who We Are?

福建菲达阀门

02

What We Can Do?

为客户提供一整套的解决方案

福建菲达阀门科技股份有限公司

中国领先的高性能蝶阀厂家

福建菲达阀门科技股份有限公司成立于2003年,是国内最大的,享有极高声誉的高性能蝶阀制造商之一。菲达公司拥有自己的阀门工厂和铸造厂,下设生产部,研发部,质量控制部以及售后服务部等部门。

菲达公司的核心产品主要为具有百万次开关性能的高性能蝶阀和各类阀门铸造件。 从产品的设计制造,加工,质量控制到售后服务,菲达公司致力于为客户提供一整套的解决方案以帮助客户在市场上具有竞争优势。同时,高科技装备助力菲达产品广泛服务于许多高端需求领域,例如核工业,生物制药工业,半导体加工等等。

自公司成立之日起,菲达公司就把解决阀门在不同极限工况下的使用作为公司的信条。我们感到自豪的是,我们的高性能蝶阀凭借可靠的性能被中国核工业集团公司选中,应用于遍及全世界的最先进的核电厂

我们的使命是:以尽可能好的价格提供最高质量的产品, 并以此为客户提供无与伦比的客户体验。

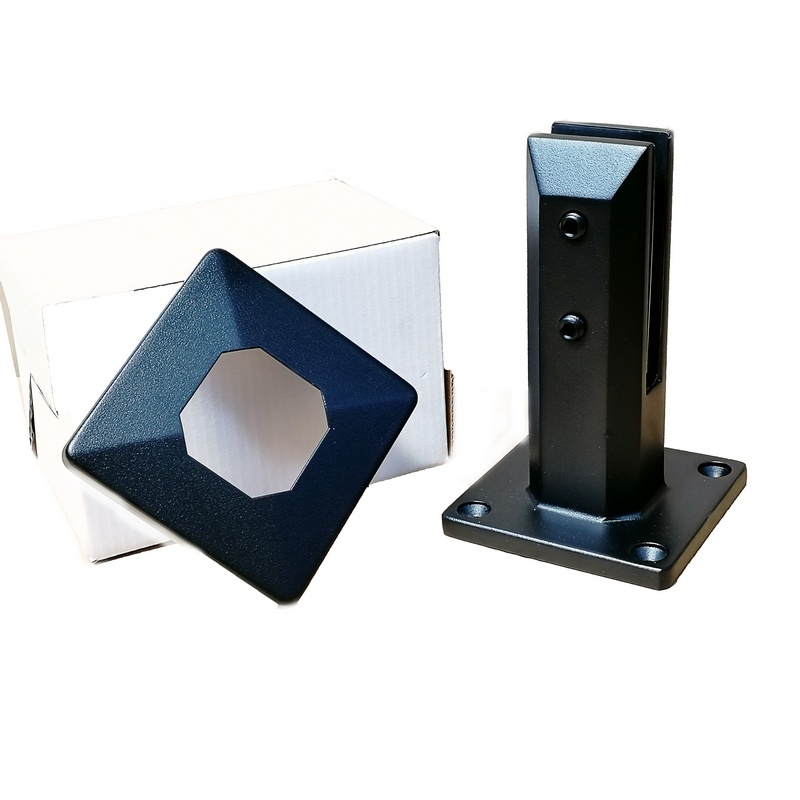

闸阀

菲达阀门生产自动化解决方案,包括:;气动执行器、液压执行器、电动执行器和执行器附件,适用于世界各地的几乎所有行业,包括:石油和天然气、采矿、电力、石化、水和废水、纸浆和造纸等。

VIEW MORE +

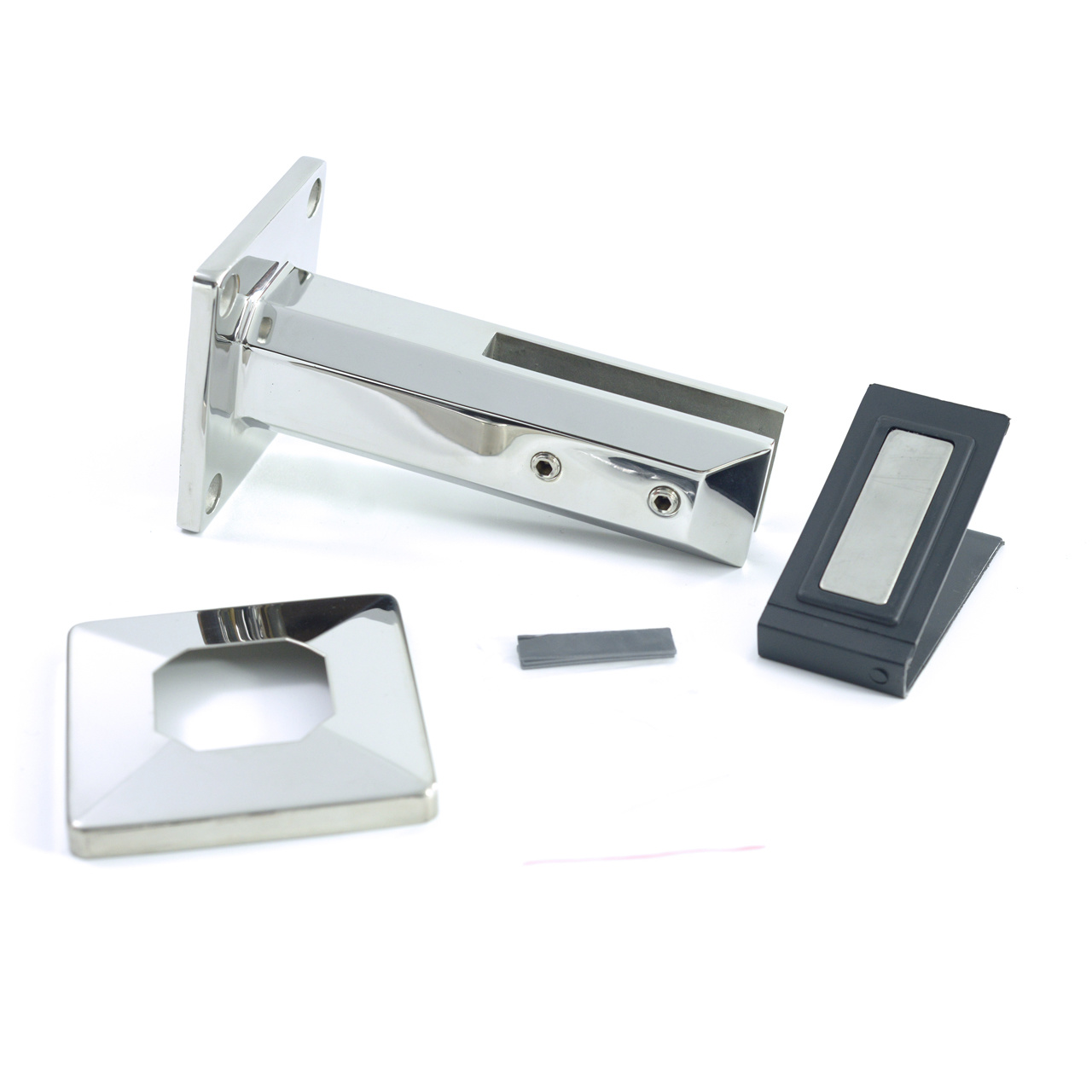

截止阀

我们经过验证的控制阀套件专为精确控制而设计,经过严格测试,可在任何工艺条件下提供一致的结果。菲达阀门解决方案在提高生产力、提高盈利能力和降低总拥有成本方面受到全世界的信赖。

VIEW MORE +

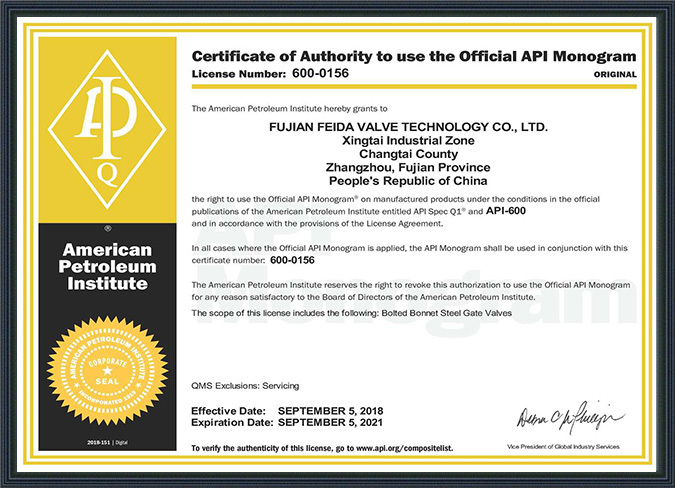

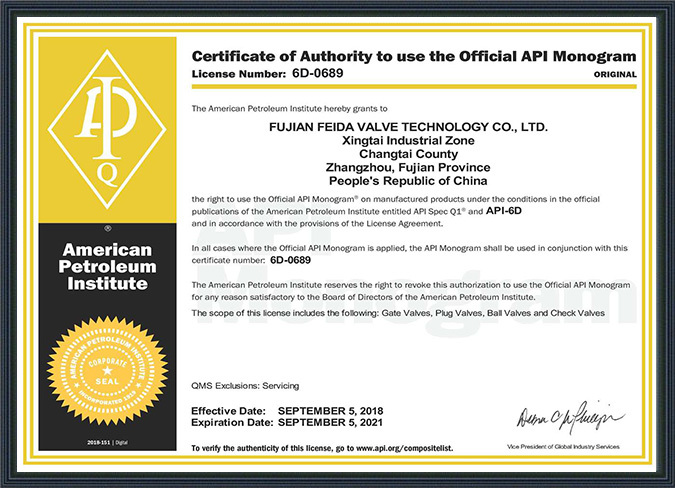

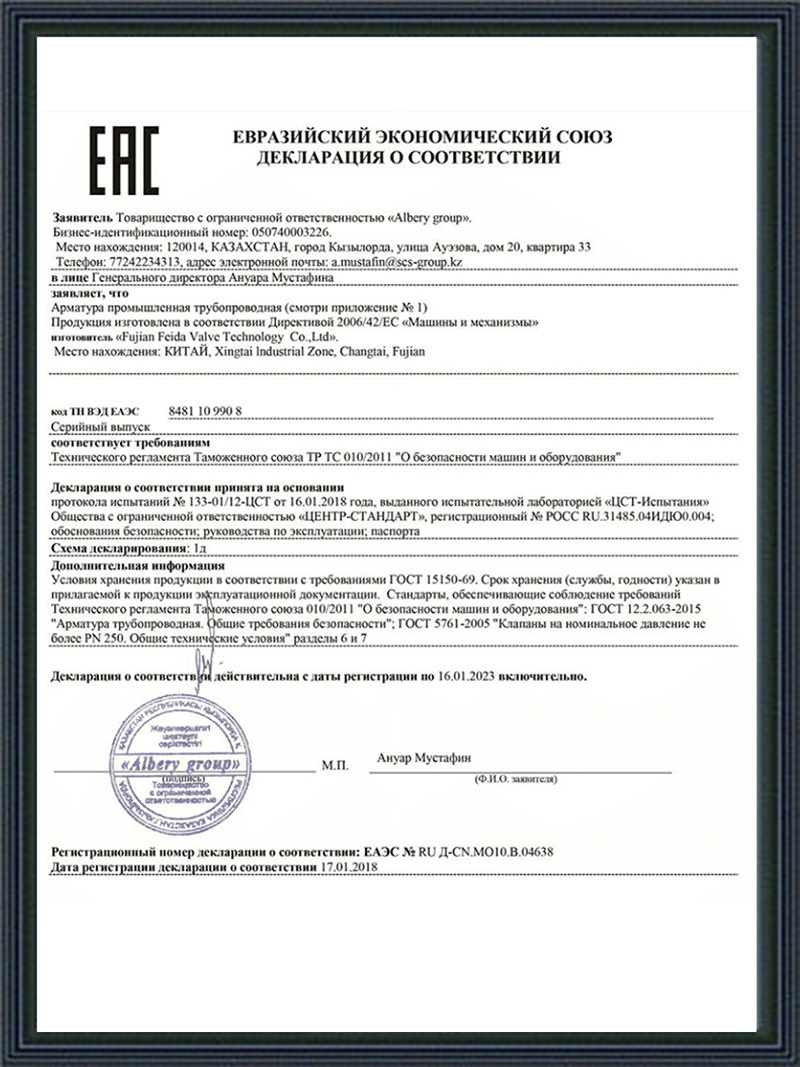

资质证书

我们真诚地邀请您到我们公司来,您的光临将使您更加信任我们,改善我们的业务关系。

新闻中心

我们真诚地邀请您到我们公司来,您的光临将使您更加信任我们,改善我们的业务关系。